Tube Laser Cutting Systems Knoxville

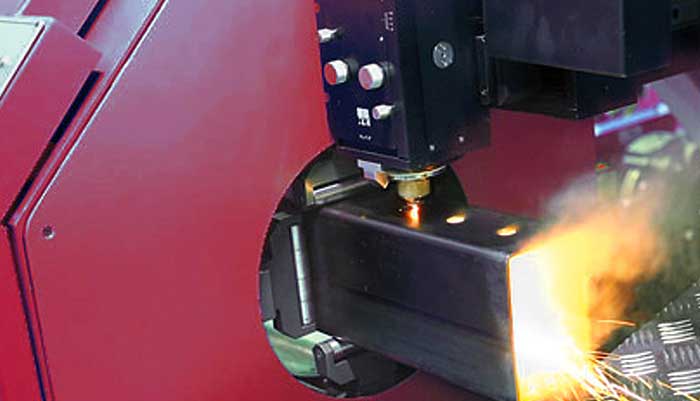

A fiber laser's operation can reveal some subtleties that are not obvious. The fiber laser beam has a much higher power density than the CO2 laser beam due to its smaller beam diameter. This not only allows the fiber laser to cut faster but also allows it to pierce quicker. The fiber is able to cut complex shapes and leave sharp edges because of the smaller beam size. Imagine cutting out a company logo from a tube, with letters spaced at 0.035 inches. A fiber can do that while a CO2 laser cannot.

The wavelength of fiber lasers is 0.06 microns. This difference is 10 times smaller than the wavelength of CO2 lasers. A fiber laser beam produces a wavelength of 1.06 microns, which is 10 percent smaller than that of a CO2 light source. However, a CO2 light source is much more likely be absorbed by reflective materials. Fiber laser cutting machines have the ability to cut brass, copper, or other reflective materials. Note that CO2 laser light that reflects off the material could not only damage the machine's optical system, but also the entire beam pathway. This risk is eliminated when the beam path is made of fiber-optic cable.